It was time to glue the elements. I used 1.6mm solid enameled copper wire which I bought from a local transformer manufacturer.

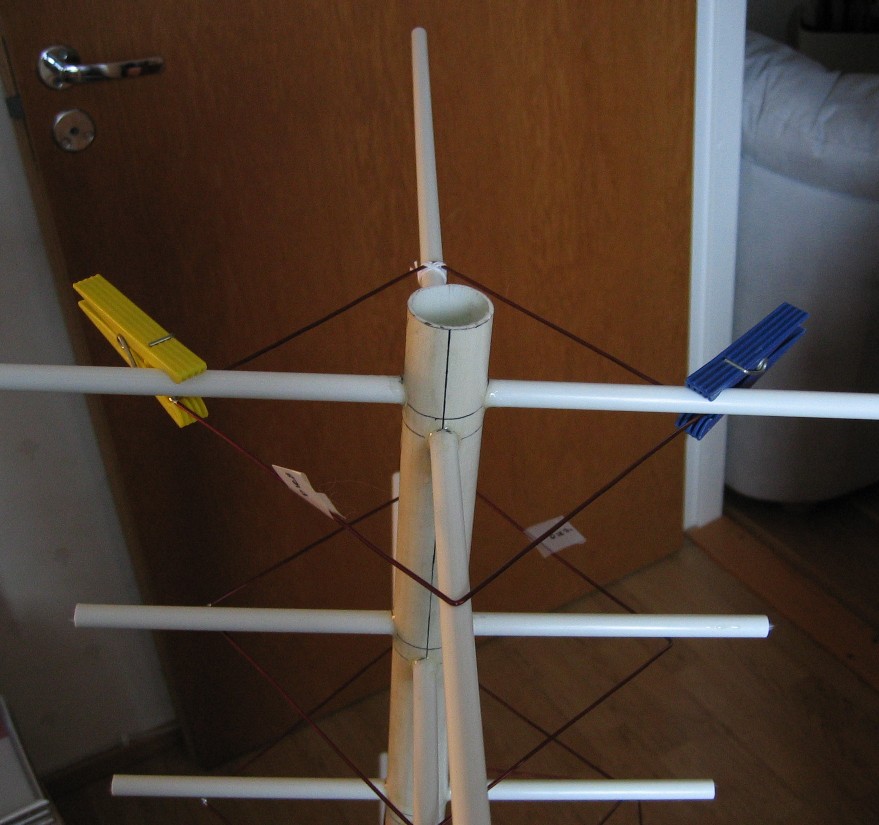

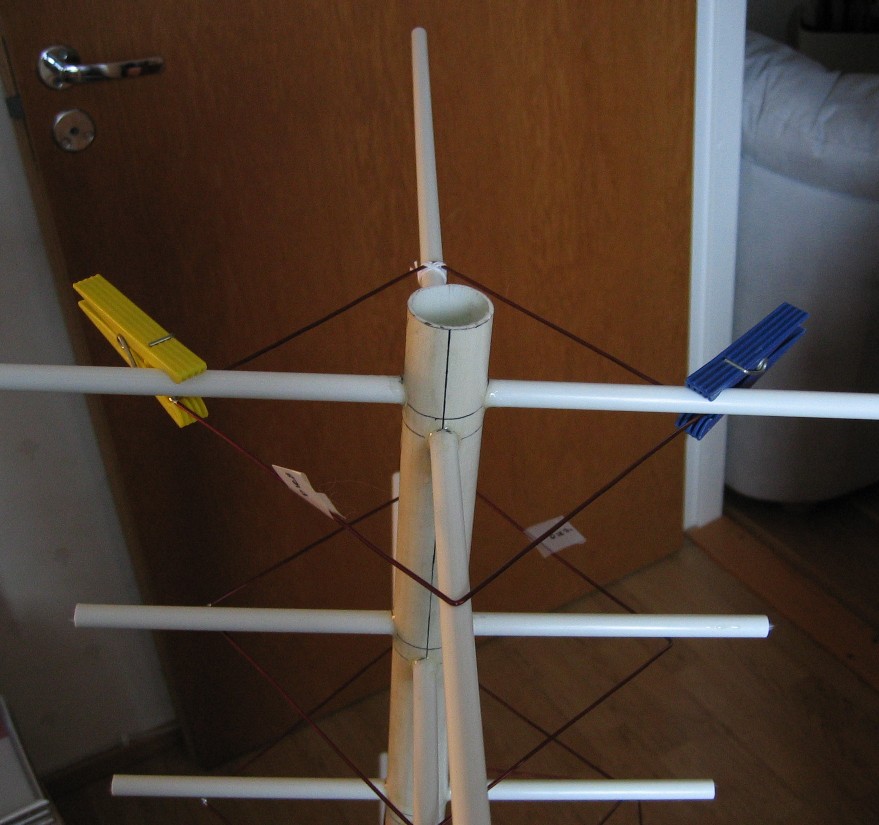

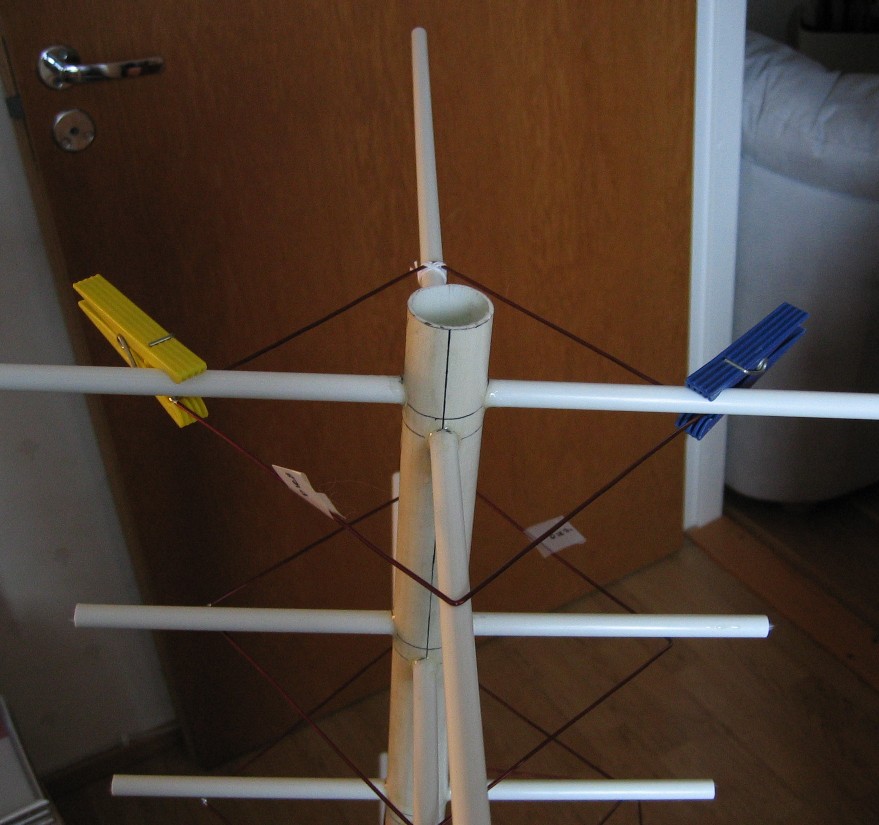

I straightened the 20 meter roll, cut the elements and bend them to a squares. I used clothes pegs to hold the elements, as you can see.

The elements were attached with strong fishing wire and then smoothed throughly with Araldite.

On the middle of the process I decided to change the feeding method of the driver element and I had to dissemble one of the glued joints.

I spent 15 minutes to get one corner of the element off. Strong, ehhh?

BACK

NEXT